|

Координатно-кинематический модуль |

|

|---|---|

|

Рабочий ход координатного стола вертикального перемещения, мм |

280 |

|

Шаг перемещений (дискретность задания ), мкм |

1 |

|

Рабочий ход перемещений разравнивателя порошка, мм, не менее |

500 |

|

Лазерно-оптический модуль |

|

|

Длина волны, мкм |

1,05-1,08 |

|

Средняя мощность, Вт |

200-300 |

|

Точность позиционирования гальваносканера, мкм, не хуже |

3 |

|

Скорость позиционирования до, мм/сек. |

9000 |

|

Поле обработки (сканирования), мм |

60х60, 100×100, 250×250 |

|

ТВ-система с выводом увеличенного изображения зоны обработки на монитор |

+ |

|

Технологический модуль |

|

|

Размеры рабочей платформы, не менее, мм |

250×250 |

|

Максимальная температура нагрева рабочей платформы,°С |

250 |

|

Блок нанесения и разравнивания слоев порошка |

+ |

|

Блок дозатора порошка |

+ |

|

Возможность регулировки дозы порошка. |

диапазоне 1-30 см3 |

|

Контейнер с порошком для пополнения дозатора |

+ |

|

Бункер с контейнером для сбора излишков порошка |

+ |

|

Герметичная рабочая камера с системой заполнения и продувки камеры в процессе построения защитным газом |

+ |

|

Газовая система (подготовка и подача защитных газов) |

+ |

|

Датчик температуры, давления, процентного содержания кислорода в рабочей камере |

+ |

|

Датчик процентного содержания кислорода в помещении, Датчик расхода защитного газа |

+ |

|

Система пожаротушения |

+ |

|

Модуль управления |

|

|

Система ЧПУ |

+ |

|

Пульт управления |

Монитор, клавиатура, «мышь» |

|

Операционная система |

Windows |

|

Управляющая программа |

ML691. |

www.laserapr.ru

3d-printer metal, surpassing foreign analogues

3d-printer to create the engine components and complex metal products.

The first domestic 3d-printer for metal is markedly different from the traditional three-dimensional printing technology. The peculiarity of the Russian plant is, a more advanced delivery system of the Mother. In Russia the development of the laser light is applied to the feed point of the sintered powder. As a result, the printer performance is improved several times. This is especially true for the manufacture of large components of complex shape.

Technology is awaiting funding!

Description 3d-printer for metal

Description metal powders for 3d-printer for metal

Advantages of metal 3d-printer

3d-printer used for metal

Description 3d-printer for metal:

The Russian development laser radiation supplied to feed point sinterable powder. As a result, the printer performance is improved several times. This is especially true for the manufacture of large components of complex shape.

Nozzle — a kind crane, where powder is fed printing. It includes a cooling circuit and a gas supply system in the fusion zone.

Russian nozzle option would immediately bake the powder at the site of delivery in the contour of the workpiece. For this optical system is also used for feeding and melting the powder in calculation place.

3d-printer is designed to seal the major elements and components of aircraft engines, made from heat-resistant and refractory metals — supports and combustors.

Traditionally used for the production of these special parts tooling and a lot of time — the production start-up cycle of a particular part may take from 3 to 6 months. When «printing» on the 3d-printer, this takes only about 48 hours.

Description metal powders for 3d-printer for metal:

Currently, the actual problem is the issue of domestic metal powders. In particular, already established Russian powders heat-resistant nickel-based alloy.

the first pilot batch of aluminum powder in Russia also released for 3D-Printer: during the tests, he proved himself better, than the German equivalent, which is used in the 3d-printers. Despite, that the two powders was identical chemical composition, from Russian raw materials to get the item with the best physical attributes.

Advantages of metal 3d-printer:

— a significant reduction in production costs,

– providing metallic components and parts with a complicated structure and configuration,

— High performance due to the laser supply in the feed point of the sintered powder — this is especially true for the manufacture of large components of complex shape,

– 3d-printer It has a nozzle, which allows immediate bake powder in place on the workpiece feed circuit,

— more sophisticated material feeding system,

— 3d-printer can replace outdated and costly in engine technology — casting and stamping parts,

— extension of life and reduced maintenance costs due to the technology of additive technologies, which allow you to restore and direct the work of the faulty part.

3d-printer used for metal:

– aircraft industry,

– manufacture of parts for spacecraft,

– engineering and metalworking,

– medical industry,

– reconditioning of parts.

RECOMMENDATIONS FOR THE USE OF TECHNOLOGY

CALL: +7-908-918-03-57

or use the search analogue technologies:

The unique technology SEARCH

or write to us here…

card site

To come in check in

Victor PotekhinI received a question regarding pyrolysis plants for MSW incineration. answered. In particular, explained, that there are different pyrolysis installation: for combustion 1-4 hazard class and the rest. Accordingly, different technologies and prices.

We receive a lot of requests for purchase of various goods. We do not sell or produce. But we maintain relationships with manufacturers and can recommend, give advice.

2018-05-18 11:08:11Victor PotekhinArrived in question hydroponnomu green feed. answered: we do not sell it. Asked to leave the application in the comments to, to its producers have fulfilled this request.

2018-05-18 17:44:35Victor PotekhinWe receive a lot of questions about technology. Please ask these questions below in the comments to records.

2018-05-23 07:24:36Andrey-245Not quite clear. This battery can not be charged at all or something? How many volts it produces? Where to buy? And is it possible to connect such series-parallel, collecting a normal battery, eg, for electric vehicle?

2018-08-23 10:09:48SergeyShef good afternoon! Interesting the above installation. How can it be ordered ? What are the terms of cooperation from the author? 2018-08-27 17:07:42Victor PotekhinSergei, throw a link here to install. Or e-mail me [email protected]

2018-08-27 18:52:14SergeyShefI have asked you, how and where it can be bought?

2018-08-27 21:07:41SergeyShefWho made the sample, that you in the photo and whether to make to order?

2018-08-27 21:10:05Victor Potekhincan not understand, that during installation. throw off the link here

2018-08-27 23:15:16Victor PotekhinWe do not possess such information

2018-08-28 21:45:17NPC-soundgood afternoon! SergeyShef product similar to, It is represented title, and in principle, any article of the LTCC technology can be made at our factory JSC «NPC «SpetsElektronSistemy». We are in g. Moscow. You can write me an email [email protected]

In our production there are probably the most complete set of equipment in Russia, which allows 3D micro, including LTCC technology, in a closed loop, from incoming inspection of materials, all intermediate production processes …

2018-08-29 18:47:20JahanCryogels for plant growth and development under adverse conditions. who produce, how to find, to buy?

2018-08-30 23:48:23Victor Potekhinyou can buy from the manufacturer

2018-09-01 20:58:09Andrey-245Hello, Victor. I asked the question (2018-08-23) I meant about carbon battery, which serves as a 100 years old.

2018-09-18 12:15:33Victor Potekhinall information, that is, on the battery, It is written in the corresponding article.

2018-09-18 20:47:11Victor PotekhinTo get information about site technology manufacturers, write the bottom of the page — in FaceBook comments

2018-09-29 20:58:40DenssikAll the good days! I’m head of the center which developed the robot, on all matters concerning cooperation can write to the post office [email protected]

2018-10-03 17:19:46Victor PotekhinDenssik, Write pzhl about any work in question?

2018-10-03 19:10:33DS-SurferIf anyone there interested in «COMPLEX WATER BY hydrowave», I beg to contact me: [email protected] Sergei.

The settings are made and implemented.

good afternoon.

I am interested in the technology of processing of APG.

Please send your contact information to [email protected]

To post messages in the chat you need to login

3d printing technology metal

3d printers print metal

3d printers Russian production

3d printers 3d printing technology

3d printing metal

metal powders for 3d printer

3d printers industrial metal

Professional 3d printer

factor demand 171

comments powered by HyperCommentsxn--80aaafltebbc3auk2aepkhr3ewjpa.xn--p1ai

3D-печать металлами — технологии и принтеры / Блог компании Top 3D Shop / Хабр

3D-печать металлом становится все более популярной. И это не удивляет: каждый металлический материал для печати предлагает уникальное сочетание практических и эстетических свойств для того, чтобы удовлетворить требования предъявляемые к различным продуктам, будь то прототипы, миниатюры, украшения, функциональные детали или даже кухонные принадлежности.

Причины печатать металлами настолько веские, что 3D-печать металлами уже внедряется в серийное производство. На самом деле, некоторые 3D-печатные детали уже догнали, а какие-то и превзошли своими свойствами те, что производятся традиционными методами.

Традиционное производство из металлов и пластиков очень расточительно — в авиапромышленности, например, до 90% материалов уходит в отходы. Выход продукции, в некоторых отраслях, составляет не более 30% от использованного материала.

3D-печать металлами потребляет меньше энергии и сокращает количество отходов до минимума. Кроме того, готовое 3D-печатное изделие может быть до 60% легче, по сравнению с фрезерованной или литой деталью. Одна лишь авиационная промышленность сэкономит миллиарды долларов на топливе — за счет снижения веса конструкций. А ведь прочность и легкость нужны и в других отраслях. Да и экономичность тоже.

3D-печать металлом дома

Что можно сделать, если появилось желание попробовать 3D-печать металлом в домашних условиях? Для печати металлом необходимы чрезвычайно высокие температуры, вряд ли вы сможете использовать обычный FDM 3D-принтер для этого, по крайней мере пока. Ситуация может измениться через несколько лет, но сейчас домашней 3D-технике это недоступно.

Если вы хотите сделать выглядящие металлическими распечатки у себя дома, лучший вариант — использование пластика содержащего частицы металла.

Такого например, как Colorfabb Bronzefill или Bestfilament Bronze.

Эти филаменты содержат значительный процент металлических порошков, но и достаточно пластика — для печати при низкой температуре любым 3D-принтером. В то же время, они содержат достаточное количество металла, чтобы соответственно выглядеть, ощущаться и иметь вес близкий к весу металлического предмета.

Изделия из филамента содержащего железо даже покрываются ржавчиной в определенных условиях, что добавляет правдоподобности, а вот проржаветь насквозь и испортиться от этого не смогут — и в этом их преимущество перед настоящими металлическими предметами.

Плюсы таких материалов:

- Уникальный внешний вид распечаток

- Идеально подходит для бижутерии, статуэток, предметов домашнего обихода и декора

- Высокая прочность

- Очень малая усадка во время охлаждения

- Подогреваемый стол не обязателен

Минусы:

- Низкая гибкость изделий, зависит от конструкции распечатки

- Не считается безопасным при контакте с пищей

- Требует тонкой настройки температуры сопла и скорости подачи филамента

- Необходима постобработка изделий — шлифовка, полировка

- Быстрый износ сопла экструдера — филамент с металлом очень абразивен, по сравнению с обычными материалами

Общий температурный диапазон печати обычно составляет 195°C — 220°C.

3D-печать металлом в промышленности

Если вы хотите приобрести 3D-принтер печатающий настоящим металлом, для использования на предприятии, то тут для вас две новости — хорошая и плохая.

Хорошая новость состоит в том, что их ассортимент достаточно широк и продолжает расширяться — можно будет выбрать такой аппарат, который соответствует любым техническим требованиям. Далее в статье можно убедиться в этом.

Плохая же новость одна — цены. Стоимость профессиональных печатающих металлом принтеров начинается где-то от $200000 и растет до бесконечности. Кроме того, даже если вы выберете и приобретете самый недорогой из них, отдельным ударом станет покупка расходников, плановое обслуживание с заменой узлов, ремонт. Не забываем и о персонале, и расходах на постобработку изделий. А на стадии подготовки к печати понадобится специальное ПО и умеющие обращаться с ним люди.

Если вы готовы ко всем этим тратам и трудностям — читайте дальше, мы представим несколько очень интересных образцов.

3D-печать металлом — применение

В некоторых промышленных секторах уже используют металлические 3D-принтеры, они стали неотъемлемой частью производственного процесса, о чем обычный потребитель может и не подозревать:

Наиболее распространенным примером являются медицинские импланты и стоматологические коронки, мосты, протезы, которые уже считаются наиболее оптимальным вариантом для пациентов. Причина: Они могут быть быстрее и дешевле изготовлены на 3D-принтере и адаптированы к индивидуальным потребностям каждого пациента.

Второй, столь же часто встречающийся пример: ювелирное дело. Большинство крупных производителей постепенно переходит от 3D-печати форм и восковок к непосредственной 3D-печати металлом, а печать из титана позволяет ювелирам создавать изделия невозможного ранее дизайна.

Кроме того, аэрокосмическая промышленность становится все более и более зависима от 3D-печатных металлических изделий. Ge-AvioAero в Италии — первая в мире полностью 3D-печатная фабрика, которая выпускает компоненты для реактивных двигателей LEAP.

Следующая отрасль использующая 3D-принтеры по металлу — автопром. BMW, Audi, FCA уже серьезно рассматривают применение технологии в серийном производстве, а не только в прототипировании, где они используют 3D-печать уже многие годы.

Казалось бы — зачем изобретать велосипед? Но и здесь 3D-печать металлом нашла применение. Уже несколько лет производители велосипедных компонентов и рам применяют 3D печать. Не только в мире, но и в России это получило распространение. Производитель эксклюзивных велосипедов Triton заканчивает проект с 3D-печатным элементом титановой рамы, это позволило снизить ее вес без ущерба прочности.

Но прежде, чем 3D-печать металлами действительно захватит мир, необходимо будет преодолеть несколько серьезных проблем. В первую очередь — это высокая стоимость и низкая скорость производства больших серий этим методом.

3D-печать металлом — технологии

Многое можно сказать о применении печатающих металлом 3D-принтеров. Есть своя специфика, но основные вопросы такие же, как и с любыми другими 3D-принтерами: программное обеспечение и аппаратные ограничения, оптимизация материалов и печать несколькими материалами. Мы не будем говорить о программном обеспечении много, упомянем лишь, что наиболее крупные издатели, такие как Autodesk, SolidWorks и SolidThinking — все разрабатывают программные продукты для использования в объемной печати металлами, чтобы пользователи могли воплотить в жизнь изделие любой вообразимой формы.

В последнее время появились примеры того, что 3D-детали напечатанные металлом могут быть столь же прочными, как традиционно производимые металлические компоненты, а в некоторых случаях и превосходят их. Созданные с помощью DMLS, изделия имеют механические свойства такие же, как у цельнолитых аналогов.

Посмотрим же на имеющиеся металлические технологии 3D-печати:

Процесс # 1: Послойное сплавление порошка

Процесс 3D-печати металлами, которым наиболее крупные компании пользуются в наши дни, известен как сплавление или спекание порошкового слоя. Это означает, что лазерный или другой высокоэнергетический луч сплавляет в единое целое частицы равномерно распределенного металлического порошка, создавая слои изделия, один за другим.

В мире есть восемь основных производителей 3D-принтеров для печати металлом, большинство из них расположены в Германии. Их технологии идут под аббревиатурой SLM (выборочное лазерное плавление) или DMLS (прямое спекание металла лазером).

Процесс # 2: Binder Jetting

Еще один профессиональный метод с послойным соединением — склеивание частиц металла для последующего обжига в высокотемпературной печи, где частицы сплавляются под давлением, составляя единое металлическое целое. Печатная головка наносит соединительный раствор на порошковую подложку послойно, как обычный принтер на листы бумаги, после чего изделие отправляется в обжиг.

Еще одна похожая, но отличающаяся технология, в основе которой лежит FDM печать — замешивание металлического порошка в металлическую пасту. С помощью пневматической экструзии, 3D-принтер выдавливает ее, подобно тому, как строительный 3D-принтер делает это с цементом, чтобы сформировать 3D-объекты. После того, как нужная форма напечатана, объекты также спекают в печи. Эту технологию использует Mini Metal Maker — возможно, единственный более-менее доступный 3D-принтер для печати металлом ($1600). Прибавьте стоимость небольшой печки для обжига.

Процесс # 3: Наплавление

Можно подумать, что среди технологий печатью металлом отсутствует похожая на обычную FDM, однако, это не совсем так. Вы не сможете плавить металлическую нить в хот-энде своего 3D-принтера, а вот крупные производители владеют такой технологией и пользуются ею. Есть два основных способа печатать цельнометаллическим материалом.

Один из них называется DED (Directed Energy Deposition), или лазерная наплавка. Он использует лазерный луч для сплавления металлического порошка, который медленно высвобождается и осаждается из экструдера, формируя слои объекта с помощью промышленного манипулятора.

Обычно это делается внутри закрытой камеры, однако, на примере компании MX3D, мы видим возможность реализации подобной технологии в сооружении настоящего полноразмерного моста, который должен быть распечатан в 2017 году в Амстердаме.

Другой называется EBM (Electron Beam Manufacturing — производство электронным лучом), это технология формирования слоев из металлического сырья под воздействием мощного электронного луча, с ее помощью создают крупные и очень крупные конструкции. Если вы не работаете в оборонном комплексе РФ или США, то вряд ли увидите эту технологию живьем.

Еще парочка новых, едва появившихся технологий, используемых пока только их создателями, представлена ниже — в разделе о принтерах.

Используемые металлы

Ti — Титан

Чистый титан (Ti64 или TiAl4V) является одним из наиболее часто используемых металлов для 3D-печати, и безусловно — одним из самых универсальных, так как он является одновременно прочным и легким. Он используется как в медицинской промышленности (в персонализированом протезировании), так и в аэрокосмической и автомобильной отрасли (для изготовления деталей и прототипов), и в других областях. Единственная загвоздка — он обладает высокой реакционной способностью, что означает — он может легко взорваться, когда находится в форме порошка, и обязательно должен применяться для печати лишь в среде инертного газа Аргона.

SS — Нержавеющая сталь

Нержавеющая сталь является одним из самых доступных металлов для 3D-печати. В то же время, она очень прочна и может быть использована в широком спектре промышленных и художественных производств. Этот тип стального сплава, содержащий кобальт и никель, обладает высокой упругостью и прочностью на разрыв. 3D-печать нержавейкой используется, в основном, лишь в тяжелой промышленности.

Inconel — Инконель

Инконель — современный суперсплав. Он производится компанией Special Metals Corporation и является запатентованным товарным знаком. Состоит, по большей части, из никеля и хрома, имеет высокую жаропрочность. Используется в нефтяной, химической и аэрокосмической промышленности (например: для создания распределительных форсунок, бортовых “черных ящиков”).

Al — Алюминий

Из-за присущей ему легкости и универсальности, алюминий является очень популярным металлом для применения в 3D-печати. Он используется обычно в виде различных сплавов, составляя их основу. Порошок алюминия взрывоопасен и применяется в печати в среде инертного газа Аргона.

CoCr — Кобальт-хром

Этот металлический сплав имеет очень высокую удельную прочность. Используется как в стоматологии — для 3D-печати зубных коронок, мостов и бюгельных протезов, так и в других областях.

Cu — Медь

За редким исключением, медь и ее сплавы — бронза, латунь — используются для литья с использованием выжигаемых моделей, а не для прямой печати металлом. Это потому, что их свойства далеко не идеальны для применения в промышленной 3D-печати, они чаще используются в декоративно-прикладном искусстве. С большим успехом они добавляются в пластиковый филамент — для 3D-печати на обычных 3D-принтерах.

Fe — Железо

Железо и магнитный железняк также, в основном, используются в качестве добавки к PLA-филаменту. В крупной промышленности чистое железо редко находит применение, а о стали мы написали выше.

Au, Ag — Золото, серебро и другие драгоценные металлы

Большинство сплавляющих слои порошка 3D-принтеров могут работать с драгоценными металлами, такими как золото, серебро и платина. Главная задача при работе с ними — убедиться в оптимальном расходе дорогостоящего материала. Драгоценные металлы применяются в 3D-печати ювелирных и медицинских изделий, а также при производстве электроники.

3D принтеры печатающие металлом

# 1: Sciaky EBAM 300 — титановый прут

Для печати действительно больших металлических конструкций лучшим выбором будет EBAM от Sciaky. Этот аппарат может быть любого размера, на заказ. Он используется, в основном, в аэрокосмической и оборонной промышленности США.

Как серийную модель, Sciaky продает EBAM 300. Он имеет размер рабочей области со сторонами 5791 х 1219 х 1219 мм.

Компания утверждает, что EBAM 300 является одним из самых быстрых коммерчески доступных промышленных 3D-принтеров. Конструкционные элементы самолетов, производство которых, по традиционным технологиям, могло занимать до полугода, теперь печатаются в течение 48 часов.

Уникальная технология Sciaky использует электронно-лучевую пушку высокой мощности для плавки титанового филамента толщиной 3мм, со стандартной скоростью осаждения около 3-9 кг/час.

# 2: Fabrisonic UAM — ультразвуковой

Другой способ 3D-печати больших металлических деталей — Ultrasound Additive Manufacturing Technology (UAM — технология ультразвукового аддитивного производства) от Fabrisonic. Детище Fabrisonic является трехосевым ЧПУ-станком, имеющим дополнительную сварочную головку. Металлические слои сначала разрезают, а затем сваривают друг с другом с помощью ультразвука. Крупнейший 3D-принтер Fabrisonic — “7200”, имеет объем сборки 2 х 2 х 1,5 м.

# 3: Laser XLine 1000 — металлический порошок

Одним из самых крупных, на рынке 3D-принтеров печатающих с помощью металлического порошка, долго являлся XLine 1000 производства Concept Laser. Он имеет область сборки размером 630 х 400 х 500 мм, а места занимает как небольшой дом.

Изготовившая его немецкая компания, которая является одним из поставщиков 3D-принтеров для аэрокосмических компаний-гигантов, таких как Airbus, недавно представила новый принтер — XLine 2000.

2000 имеет два лазера и еще больший объем сборки — 800 х 400 х 500 мм. Эта машина, которая использует патентованную технологию LaserCUSING (тип селективного лазерного плавления), может создавать объекты из сплавов стали, алюминия, никеля, титана, драгоценных металлов и из некоторых чистых материалов (титана и сортовых сталей.)

Подобные машины есть у всех основных игроков на рынке 3D-печати металлом: у EOS, SLM, Renishaw, Realizer и 3D Systems, а также у Shining 3D — стремительно развивающейся компании из Китая.

# 4: M Line Factory — модульная 3D-фабрика

Рабочий объем: 398,78 х 398,78 х 424,18 мм

От 1 до 4 лазеров, 400 — 1000 Вт мощности каждый.

Концепция M Line Factory основана на принципах автоматизации и взаимодействия.

M Line Factory, от той же Concept Laser, и работающий по той же технологии, делает акцент не на размере рабочей области, а на удобстве производства — он представляет собой аппарат модульной архитектуры, который разделяет производство на отдельные процессы таким образом, что эти процессы могут происходить одновременно, а не последовательно.

Эта новая архитектура состоит из 2 независимых узлов машины:

M Line Factory PRD (Production Unit — производственная единица)

Production Unit состоит из 3-х типов модулей: модуль дозирования, печатный модуль и модуль переполнения (лоток для готовой продукции). Все они могут быть индивидуально активированы и не образуют одну непрерывную единицу аппаратуры. Эти модули транспортируются через систему туннелей внутри машины. Например, когда новый порошок подается, пустой модуль хранения порошка может быть автоматически заменен на новый, без прерывания процесса печати. Готовые детали могут быть перемещены за пределы машины и немедленно автоматически заменяются следующими заданиями.

M Line Factory PCG (Processing Unit — процессинговая единица)

Это независимый блок обработки данных, который имеет встроенную станцию просеивания и подготовки порошка. Распаковка, подготовка к следующему заданию печати и просеивание происходят в замкнутой системе, без участия оператора.

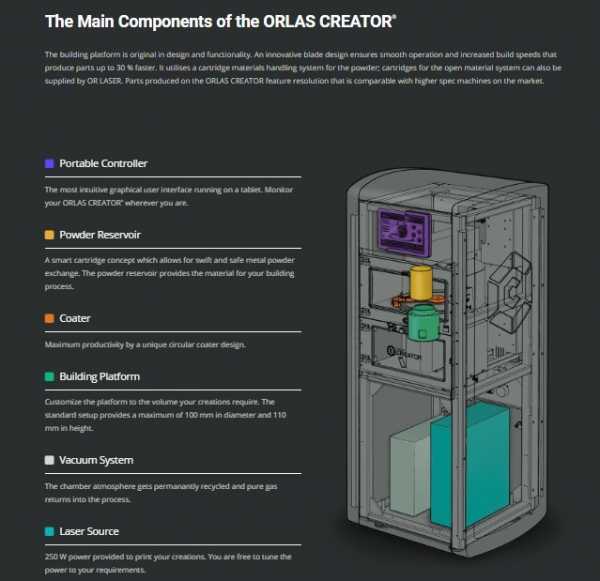

# 5: ORLAS CREATOR — 3D-принтер готовый к работе

Создатели ORLAS CREATOR позиционируют этот 3D-принтер как максимально доступный, простой в обращении и готовый к работе, не требующий установки никаких дополнительных комплектующих и программ сторонних производителей, способный печатать прямо из файла комплектной CAD/CAM их собственной разработки.

Все необходимые компоненты установлены в относительно компактном корпусе, которому необходимо пространство 90х90х200 см. Много места он не займет, хоть и выглядит внушительно, да и весит 350 кг.

Как можно понять из приведенной производителем таблицы, металлический порошок спекается вращающейся лазерной системой, слоями 20-100 мкм толщиной и с размером “пикселя” всего в 40 мкм, в атмосфере азота или аргона. Подключить его можно к обычной бытовой электросети, если ваша проводка выдержит нагрузку в 10 ампер. Что, впрочем, не превышает требований средней стиральной машины.

Мощность лазера — 250 Ватт. Рабочая область составляет цилиндр 100 мм в диаметре и 110 в высоту.

# 6: FormUp 350 — Powder Machine Part Method (PMPM)

FormUp 350, работающий в системе Powder Machine Part Method (PMPM), создан компанией AddUp — совместным проектом Fives и Michelin. Это новейший аппарат для 3D-печати металлами, впервые представленный в ноябре на Formnext2016.

Принцип работы у этого 3D-принтера тот же, что и у приведенных выше коллег, но его главная особенность в другом — она заключается в его включенности в PMPM.

Принтер предназначен именно для промышленного использования, в режиме 24/7, и рассчитан именно на такой темп работы. Система PMPM включает в себя контроль качества всех комплектующих и материалов, на всех стадиях их производства и распространения, что должно гарантировать стабильно высокие показатели качества работы, в чем у Мишлена огромный многолетний опыт.

# 7: XJET — NanoParticle Jetting — струйная печать металлом

Технология впрыска наночастиц предполагает использование специальных герметичных катриджей с раствором, в котором находится взвесь наночастиц металла.

Наночастицы осаждаются и образуют собой материал печатаемого изделия.

Учитывая заявленные особенности технологии (применение металлических частиц наноразмера), несложно поверить создателям аппарата, когда они утверждают о его беспрецедентных точности и разрешении печати.

# 8: VADER Mk1 — MagnetoJet — струйная печать металлом

Технология Зака Вейдера MagnetoJet основана на изучении магнитной гидродинамики, а конкретнее — возможности управлять расплавленным металлом с помощью магнитных полей. Суть разработки в том, что из расплавленного алюминия формируется капля строго контролируемого размера, этими каплями и осуществляется печать.

Размер такой капельки — от 200 до 500 микрон, печать происходит со скоростью 1000 капель в секунду. Рабочая область принтера: 300 мм х 300 мм х 300 мм

Рабочий материал: Алюминий и его сплавы (4043, 6061, 7075). И, пусть пока это только алюминий, но принтер в 2 раза быстрее порошковых и до 10 раз дешевле.

В 2018 году планируется выпуск Mk2, он будет оснащен 10 печатающими головками, что должно дать прирост скорости печати в 30 раз.

# 9: METAL X — ADAM — атомная диффузия

Компания Markforged представила новую технологию 3D-печати металлом — ADAM, и 3D-принтер работающий по этой технологии — Metal X.

ADAM (Atomic Diffusion Additive Manufacturing) — технология атомной диффузии. Печать производится металлическим порошком, где частицы металла покрыты синтетическим связующим веществом, которое удаляется после печати, позволяя металлу соединиться в единое целое.

Главное преимущество технологии — отсутствие необходимости применения сверхвысоких температур непосредственно в процессе печати, а значит — отсутствие ограничений по тугоплавкости используемых для печати материалов. Теоретически, принтер может создавать 3D-модели из сверхпрочных инструментальных сталей — сейчас он уже печатает нержавейкой, а в разработке титан, Инконель и стали D2 и A2.

Технология позволяет создавать детали со сложной внутренней структурой, такой как в пчелиных сотах или в пористых тканях костей, что затруднительно при других технологиях 3D-печати, даже для DMLS.

Размер изделий: до 250мм х 220мм х 200мм. Высота слоя — 50 микрон.

Того гляди, скоро можно будет распечатать высококачественный нож — с нуля, за пару часов, придав ему любой самый замысловатый дизайн.

Хотите больше интересных новостей из мира 3D-технологий?

Подписывайтесь на нас в соц. сетях:

habr.com

Отечественные ученые разработали 3d принтер для печати металлом в космосе — 3d-daily

Технологии 3d печати с каждым днем осваивают новые сферы, в которых могут успешно использоваться. Недавно группа ученых из России представила первый 3d принтер, который может использоваться в космосе. Исследования проводились совместно с «Томской электронной компанией», а руководитель проекта, Григорий Семенов, уже был замечен ранее с тематическим докладом в 2015 году.

Уникальное устройство для России

Обращаясь к российскому информационному агентству ТАСС, Семенов сказал, что их разработка является уникальной для Российской Федерации:

«Сегодня доминирующее положение в производстве металлических изделий начинают занимать 3d принтеры, которые используют лазерные технологии и порошковые металлы. Наше устройство в качестве наполнителя использует металлическую проволоку, что позволяет работать с тяжелыми и массивными объектами. При этом за час можно напечатать изделие, вес которого будет достигать несколько килограммов, в то время, как другие методы позволяют добиться аналогичных результатов за сутки минимум».

3d принтер получил название ТЭТА, и по словам Семенова имеет достаточно внушительные характеристики. Объем сборки может достигать 3 кубических метров, а максимальный вес предметов доходит до отметки в 1 тонну. Также устройство может работать с тугоплавкими материалами, в списке которых присутствует титан, тантал и вольфрам. При этом, особая технология позволяет устранить такие явления как окисления, а сам процесс накаливания происходит в вакууме.

3d печать для космической промышленности

Формат принтеров, наподобие ТЭТА, попадает под пристальное внимание представителей космической промышленности. Многие компании уже представляли подобные продукты, но плавка металла в открытом космосе все же остается препятствием, в силу невозможности использования классических порошковых наполнителей. ТЭТА же не имеет этих недостатков, так как его работа больше схожа с классическим FDM 3d принтером, который использует для работы пластиковую нить.

Как бы не показал себя ТЭТА в будущем, можно с уверенностью сказать, что за 3d технологиями стоит будущее освоения космического пространства. Возможно первые поселения на других планетах будут созданы именно при помощи 3d принтеров. Нам же остается только ждать, и всячески поддерживать как исследователей, так и производителей 3d оборудования.

3d-daily.ru

3D принтер по металлу: описание технологии, возможности применения |

Опубликовал: admin в Бизнес 06.03.2018 296 Просмотров

3D печать это одно из самых сложных направлений в сфере современных технологий и является важным элементом в области современного производства. С помощью принтеров, осуществляющих трехмерную печать, открываются широкие возможности, в том числе для предпринимательской деятельности. Имеются все предпосылки для того, что такая технология в недалеком будущем заменит стандартные методы производства: литье, ковка и т. п. Данная статья ответит на вопросы: что такое 3D печать по металлу и каковы главные направления развития этой технологии.

Это специальное устройство, которое дает возможность создавать металлические изделия и наносить специальные слои на формирующиеся детали. То есть формирование объекта принтером происходит послойно.

Первым делом при помощи компьютера и специальной программы создается виртуальная модель в трех плоскостях, разделенная на цифровые слои. В процессе печати объекта, из головки принтера на печатающую платформу выделяется жидкий металл или порошок, тем самым создавая начальный слой. Далее автоматически формируется следующий слой металла. И так, слой за слоем, создается готовое изделие.

Данное устройство дает возможность для изготовления самых разнообразных изделий. Используемые современные разработки очень конкурентоспособны на фоне стандартных методик производства металлических объектов.

Технология 3D печати является многофункциональной. Ее применяют в своей деятельности, как профессионалы, так и обычные любители. Спектр применения довольно обширен: изготовление сложных по форме металлических изделий, имитирование обычной ковки. Для этих целей не нужно привлекать дополнительное оборудование и устройства.

промышленный 3Д принтер

Промышленный 3D принтер способен напечатать даже двигатель для ракеты, который будет трудно отличить от оригинала, изготовленного стандартным способом. Отсюда следует вывод – эта технология может изготавливать почти любые металлические предметы.

На данный момент используется всего 2 основных способа печати изделий из металла: струйная и лазерная технология. В обоих случаях происходит последовательное нанесение слоев металла (аддитивная технология), пока на выходе не получится требуемый объект. Но технологии не стоят на месте, разработчики развивают новые методы печати.

Эта разновидность печати одновременно является и самой ранней и успешной в аддитивной технологии. Но здесь нужно четкое понимание того, что данный подход может применяться лишь для создания композитных (смесь металла с полимерами) деталей из-за специфики производства. Такой способ формирует любой трехмерный объект из порошковых материалов. Порошок смешивается с полимерами, которые помогают сырью связываться во время печати. Поэтому изготавливаемые по данной технологии изделия нельзя считать полностью металлическими.

Существует вариант, при котором композитный предмет переплавляется в цельнометаллический. Из-за пористости, данные изделия не обладаю хорошей прочностью. Для ее повышения можно прибегнуть к пропитке модели бронзой или другим металлом.

Из-за невысокой прочности изделий данную технологию используют, прежде всего, при изготовлении сувениров.

В данной технологии тонкие листы металла постепенно наносятся на платформу. Формирование происходит при помощи резки листов (металлической или лазерной) и их склеивания, в результате чего получается 3Д модель. В качестве расходного материала использоваться фольга.

Полученное изделие не является на 100 процентов металлическими. Это объясняется тем, что для придания целостности предмету применяется клей.

Главным достоинством является экономичность и близкое сходство получаемых деталей с макетом. Часто данный подход применяют для создания макетов.

В данном случае в качестве сырья используются легкоплавкие металлы. Но чистые металлы или сплавы не используются, поскольку применение такого сырья влечет понятные проблемы из-за необходимости работы принтера при высоких температурах.

Изделие из BronzeFill до и после полировки

Учитывая это, разработчики остановились на композитных материалах, подобных тем, что используются в струйной печати. Например, BronzeFill – материал из термической пластмассы и бронзового порошка. Выполненные на его основе предметы, имеют высокую схожесть с оригиналом и податливы к шлифовке. Данные изделия нельзя считать цельнометаллическими, и их характеристики ограничены используемые в сырье композитами.

Этот метод активно применяется в промышленности. С его помощью можно создавать проводники и экранирующие материалы, что может сделать значительный прорыв в печати электронных плат.

Несмотря на хорошее качество элементов, изготавливаемых при помощи лазерного плавления, их использование не столь обширно из-за значительной пористости получаемых изделий, и следовательно, их малой прочности. Данная продукция может применяться в некоторых отраслях, но совершенно не может использоваться там, где требуется противостоять большим нагрузкам.

Титановый имплант, изготовленный с помощью электронно-лучевой плавки

Проблему решает замена лазерного спекания на лазерную плавку, которая отличается лишь температурной обработкой. Последняя технология активно используется в области получения однородных деталей, которые почти не отличаются от литых аналогов.

Схожий метод имеет электронно-лучевое плавление. Такие принтеры поставляет шведская компания Arcam. Данная технология почти как и предыдущая, но имеет ряд преимуществ: отсутствие электромеханических зеркальных комплексов и высокоскоростная манипуляция с электронными пучками. По остальным критериям она мало превосходит предшественника.

На видео представлена презентация печати методом селективного лазерного спекания.

Использование различных металлов и сплавов дает возможность для создания мелких партий изделий из металла, аналогичных оригиналу. Здесь не нужна развитая инфраструктура, за счет чего достигается существенная финансовая и ресурсная экономия. Технология активно применяется при изготовлении ортопедических протезов, газовых турбин и даже форсунок для реактивных двигателей.

Это не совсем технология для трехмерной печати, а скорее для 3D ремонта. Она применяется только в промышленности из-за узкого спектра применения.

Принцип работы заключается в нанесении порошка на дефектные участки детали с дальнейшим лазерным наплавлением.

Принцип работы заключается в нанесении порошка на дефектные участки детали с дальнейшим лазерным наплавлением.

Головка может пересыщаться по пяти осям, меняя угол наклона и вращаясь относительно вертикальной плоскости. Это позволяет работать под любыми углами.

Данную технологию можно задействовать для ремонта крупных изделий, в том числе при обнаружении в них брака. К примеру, во Франции компания Beam использует данный подход для ремонта авиадвигателей и других крупных изделий.

Технология CLAD может использовать в работе герметичную камеру с инертной атмосферой, что необходимо для работы с металлами, которые поддаются оксидации (титан и т.п.).

Данная технология нашла применение у специалистов НАСА. Так как в невесомости не представляется возможным работа с порошками, вместо них используются металлические нити. Работа аналогична послойной 3Д печати, но происходит с применением электронно-лучевой пушки для плавки.

Специалисты НАСА проводят испытания прототипа EBFȝ в условиях искусственной невесомости

Данная технология поможет создавать запасные детали на орбите, что избавит от необходимости их доставки с Земли.

Сейчас на рынке представлено большое количество 3D принтеров, позволяющих печатать трехмерные объекты из металла. Наиболее качественные промышленные принтеры могут стоить несколько десятков тысяч долларов США. Конечно, есть и более дешевые образцы, но их качество печати соответственно хуже. При этом разработчики постоянно совершенствуют свою продукцию, и следует ожидать, что в ближайшем будущем будут появляться все более дешевые принтеры, позволяющие печатать все более качественные изделия.

На видео представлена струйная технология 3D печати по металлу.

mari-a.ru

Технология 3D-печати в промышленности — Мanufactory-Industry-Design

Аддитивное производство за последние 7 лет получило невероятный толчок развития. Возможность создавать изделия сложных геометрических конфигураций открыло перед трехмерной печатью дорогу в промышленные и научные сферы. Модели, построенные по цифровым аналогам, не уступают по качеству традиционным деталям. Стоит ли утверждать, что за такой инновационной технологией стоит будущее? Попробуем проанализировать все факты и разобраться о перспективах технологии 3D-печати.

В этой статье будет рассказано о том, где и как применяется 3D-печать в промышленной сфере. Сумеет ли она заменить традиционные механические способы обработки или останется полем для тестирования? Прочитайте статью до конца и получите ответы на эти вопросы.

Какие принципы лежат в основе работы 3D-притнера?

Работа промышленного 3D-принтера строится на обработке трехмерных графических файлов с геометрическими параметрами будущего объекта. Создаются они инженерами вручную на компьютере или путем сканирования реальных прототипов.

Устройство обрабатывает данные с файлов и формирует структуру из слоев жидкого, порошкообразного или листового материала. Будущая деталь образуется последовательным соединением слоев через поперечные сечения. Каждый микрон поверхности соответствует виртуальным параметрам графической модели и сплавляется воедино в цельную модель готовой формы.

В каких отраслях применяется трехмерное производство?

Технология 3D-печати стала противоположностью привычным фрезеровальным и режущим станкам. В стандартном производстве детали формируется путем удаления лишних слоев. В 3D-принтерах ситуация строится противоположным способом. Здесь отсутствуют отходы материалов и достигается максимальная точность изготовления. Именно это позволяет коммерческим предприятиям и заводам обращать все большее внимание на экономически выгодную технологию производства.

Трехмерная печать успешно закрепились в 5 отраслях:

- строительной;

- автомобильной;

- аэрокосмической;

- медицинской;

- военной.

Связанно это с тем, что методика позволяет создавать геометрические формы неограниченной сложности. Таких результатов невозможно достичь с ограниченностью стандартного производственного оборудования. Перед инженерами и конструкторами открываются новые возможности и перспективы развития революционных технологий. Но какие материалы получается обрабатывать?

Из каких материалов делаются изделия на 3D-принтерах?

К 2017 году для аддитивного производства в промышленной сфере доступно больше 10 методов. Отличаются они технологией формирования слоев и обрабатываемых материалов. Каждый отдельный способ открывает возможности создания моделей из термопластиков или даже титановых сплавов.

Рассмотрим детально 5 основных методик:

- Моделирование методом послойного наплавления. Экструзионная методика позволяет использовать для работы термопластики, включая полилактиды.

- Моделирование форм методом электронно-лучевой плавки. Проволочный и порошковый методы дают возможность создавать изделия из большинства стандартных сплавов металла.

- Прямое лазерное спекание металлов. Технология порошкового метода позволяет создавать титановые сплавы, которые отличаются высочайшей прочностью и свойствами

- Выборочная лазерная плавка. Кроме титановых изделий можно создавать объекты из сплавов кобальт-хрома, нержавеющей стали и алюминия. Изделия отличаются высокой плотностью и не уступают механически обработанным аналогам.

- Выборочное лазерное спекание. Методика вместе с металлами позволяет изготавливать модели из полистирола, армированного стекловолокна, полиамидов и армированного углеволокна.

С 3D-технологией промышленное производство получило возможности значительно ускорить рабочие процессы, а затраты на реализацию готового изделия снизить в разы.

Перспективы и инновационные разработки на 3D-принтерах

Современные гиганты промышленной индустрии давно взяли себе на вооружение технологию 3D-печати. Если останавливаться подробнее, то стоит отметить достижения отдельных компаний.

В 2015 году General Electric успешно запустило производство сопел для ракетных двигателей. Крупногабаритные принтеры выпускают инновационную продукцию для двигателей нового поколения из композитного углеродного волокна и композитов с керамической матрицей (CMC). Этапы тестирований уже доказали, что полученные сопла в 5 раз прочнее предшественников. Достигается это за счет того, что конструкция имеет цельную монолитную форму. Больше не требуется собирать детали из 30 отдельных частей и постоянно добавлять сварные швы и припои.

Британская компания Rolls-Royce использует 3D-технологию для создания авиадвигателей, наравне с другими авиастроителями. С помощью инновационных методик запущен процесс создания отдельных элементов и деталей для двигателей. Руководители проектов видят перспективы и говорят о возможностях экспериментировать с параметрами изготавливаемых конструкций. Принтеры позволяют легко изменить геометрические параметры деталей, не меняя при этом всю производственную линию.

Аналогичным образом используют аддитивные технологии трехмерной печати компании NASA и AirBus. Если последняя использует принтеры для изготовления авиационных деталей, то космический гигант нацелен на покорение космоса. В 2016 году был запущен проект Sinterhab, который позволит «печатать» базы прямо на поверхности луны. В качестве строительного материала будет использоваться лунный реголит, из которого будут создавать цельные строительные блоки. NASA также рассматривает перспективы автономной печати ремонтных частей и деталей прямо с орбиты корабля. В будущем на этом планируется сэкономить миллиарды вместо затратных транспортировок грузовых шатлов.

Будущее уже наступило. Применение 3D-принтеров в коммерческой сфере

Самое главное – технология трехмерной печати уже доступна обычным коммерческим предприятиям. Если раньше позволить себе крупногабаритный 3D-принтер могли только крупные компании, то сейчас стоимость оборудования доступна и обычным фабрикам. Средняя цена промышленного принтера находится в диапазоне от 5000 до 15000$.

На рынке промышленного оборудования в свободном доступе уже представлены свыше 100 моделей. Основные отличия заключаются в размерах печатных изделий, материалах для изготовления, скорости создания и технологии нанесения слоев.

- 3D-принтеры BetAbram и WinSun. Используются в строительных компаниях для создания настоящих полноразмерных домов. Проекты пользуются большой популярностью в Европе и Америке. Он создает отдельные элементы для каркасных домов со сложной архитектурной формой.

- 3D-принтер Concept Laser X-Line 2000R. Позволяет плавить металл и создавать из него промышленные компоненты для деталей машиностроения. Полученные изделия ничем не отличаются по свойствам от деталей, сделанных на обычных станках. При этом скорость производства увеличивается на 35%.

- 3D-принтер Stratasys Rortus 900mc. С его помощью компании создают сверхточные детали, инструменты и прототипы для других заводов. Методика позволяет изготавливать сверхточные шаблоны для литейного производства, запчасти и прототипы многих устройств.

Если обобщить информацию, то появляется смелый вывод. 3D-печать нашла активное применение в промышленности. Технология была доступна еще 30 лет назад, но высокая себестоимость не позволяла предприятиям в полной мере использовать возможности аддитивных разработок. Результаты 2017 года говорят о том, что промышленная 3D-печать не остановиться на достигнутом, а станет революционным методом в решении сложных инженерных задач.

www.tehnohacker.ru

3D печать по металлу: виды принтеров и обзор мирового рынка

В настоящее время 3D печать металлом является одной из наиболее перспективных технологий, постепенно вытесняющая современные методы макетирования.Исследователи усердно работают над тем, чтобы в ближайшее время принтеры, печатающие металлом, появились на строительных площадках, в металлургической промышленности и на пищевом производстве.Подробнее разберемся с тем, что представляют собой современные 3D принтеры для печати металлом.

На данный момент существует всего несколько технологий, которые используются для печати металлом: лазерные 3D принтеры и струйные. Обе они подразумевают аккуратное и постепенное наслаивание «чернил» слой за слоем для построения заданной фигуры. Тем не менее, инженеры нашли сразу несколько способов, позволяющих вырастить твердый объект на платформе построения.

Технология SLS, также известная под названием Direct metal laser sintering (селективное лазерное спекание), позволяет создавать металлические объекты из плавкого порошка – металлической глины. Впервые данный материал был показан в 1990 г. в Японии. Металлоглина изготавливается из смеси металлической стружки, органического связующего вещества и воды. При обжигании лазерным излучением связующее вещество и вода выгорают, что превращает металлический порошок в монолитный объект по запрограммированному шаблону. Печать проходит в специальной камере с бескислородной средой, в которой постоянно поддерживается высокая температура.

Электронно-лучевая плавка, или EBM, практически не отличается от SLS/DMLS печати металлом. Единственное отличие заключается в том, что вместо лазерного луча металлоглина плавится при помощи направленных электроимпульсов. Использование электронных пучков высокой мощности, действующих в вакууме, обеспечивает более высокую детализацию печатных объектов, поскольку корректировка электронного луча осуществляется не за счет движения печатной головки, а с помощью манипуляции магнитными полями, т.е. на гораздо более точном уровне, а также делает EBM принтеры более рентабельными в сравнении с лазерным оборудованием и обеспечивает более высокую производительность.

Технология FDM, или fused deposition modeling (струйное моделирование методом наплавления) используется преимущественно в принтерах, работающих с пластиком, воском и смолами. Принцип работ устройств, использующих данную технологию достаточно прост: расплавленный материал выдавливается через экструдер на охлажденную платформу построения, где он застывает, слой за слоем формируя нужный объект. 3Dпечать из металла способом наплавления рассматривается как самый простой из доступных ныне методов печати металлом, не лишенный недостатков: несмотря на обилие «чернил», доступных в виде металлоглины (медь, сталь, железо, бронза, серебро и золото), существующее FDM оборудование не способно печатать металлические объекты с высокой четкостью и детализацией.

В компаниях, использующих на производстве EBM и SLS/DMLS принтеры (например, General Electric, Mitsubishi, Boeing, General Motors и др.), уверяют, 3D печать помогает им экономить значительные денежные суммы и существенно расширить возможности конвейерного производства комплектующих.

ПЕРЕВОД СТАТЬИ:

Фирма «MarketsandMarkets» (Пуна, Индия) опубликовала сообщение «Рынок 3Dпринтеров по металлу по форме (порошок или волокно), по типу (титан, никель, нержавеющая сталь, алюминий и др.), по применению (воздушно-космическая оборона, автомобильная отрасль, медицина и стоматология, др.) и по региону – мировой прогноз до 2020 г.» Расчеты этой фирмы показывают: к 2020 г. ожидается, что мировой рынок достигнет $776,8 млн, при совокупном среднегодовом темпе роста 31,5% на протяжении 2015-2020 гг.

Ожидается, что рынок 3Dпечати металлами вырастет на большую величину совокупного среднегодового темпа роста в Азиатско-Тихоокеанском регионе по сравнению с другими областями. Технологическое совершенствование, увеличение объема выпуска продукции, разработка новых товаров и истечение срока основного патента для селективного лазерного спекания на основе порошка – это факторы, влияющие на общий спрос.

Ожидается, что сегмент металла титана будет превалировать на мировом рынке 3Dпечати по металлу, потому что этот процесс широко внедрен в аэрокосмическую и оборонную промышленности, которые используют титан и его сплавы в деталях двигателей. Эти производства составляют более 1/3 совокупного рынка конечных пользователей 3D принтеров по металлу.

На автомобильном, медицинском и стоматологическом рынках доступность новых материалов для обработки и моделирования, спрос на ортопедические и зубные имплантаты и высокий уровень капиталовложений в разработку новой продукции будут способствовать росту 3Dпечати по металлу.

Северная Америка считается самым главным региональным рынком в 3Dметаллопечати.

Статья из журнала «Canadian Metalworking», май 2016 г.

Обзор и перевод подготовила Елена Михаленко

pronowosti.ru